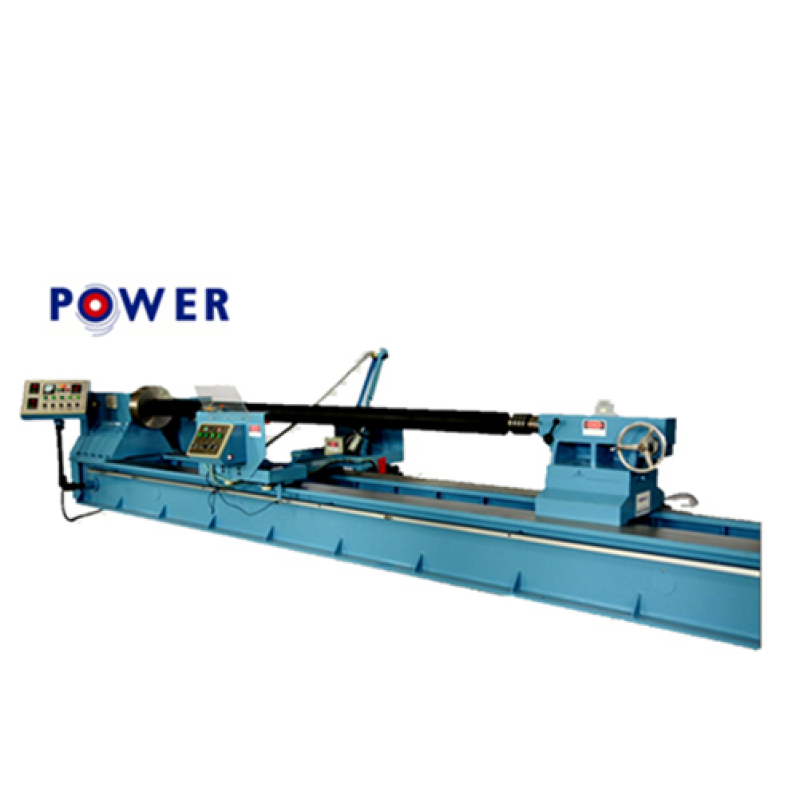

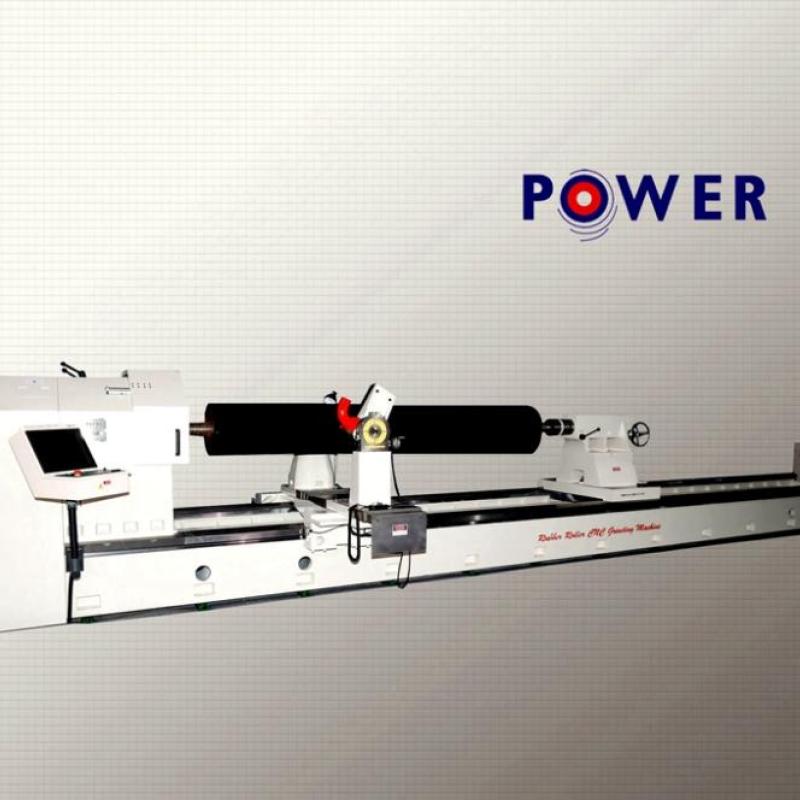

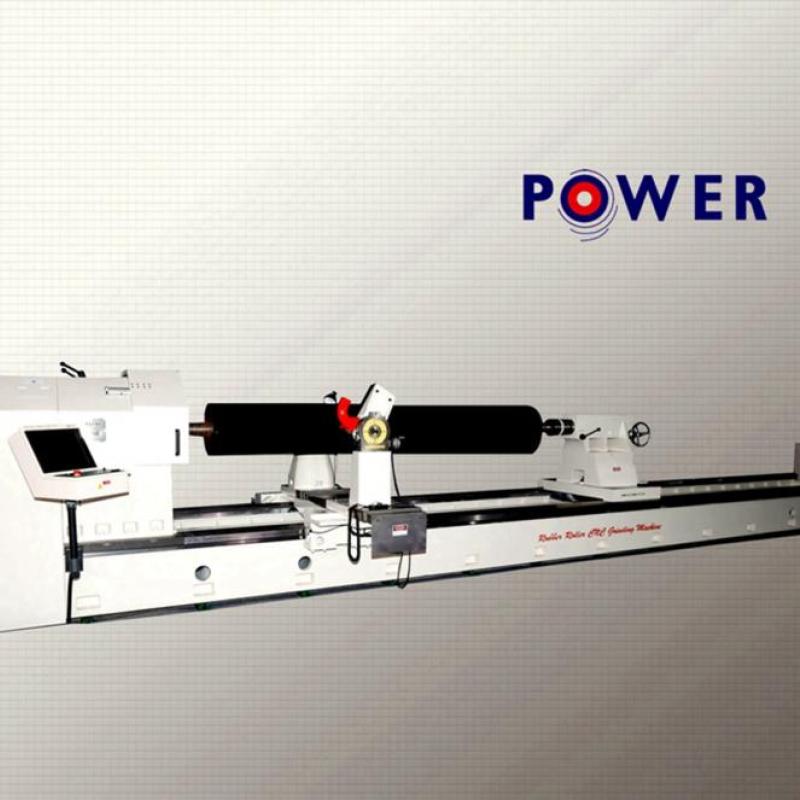

1. Factory custom designed rubber curler groover has our personal advanced user-pleasant CNC running gadget.2. The modern CNC gadget can without difficulty perform extra than 35 shapes at the rubber curler surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, immediately groovings, etc. 3. Remote trouble fixing characteristic availabe.4. Having all of the capabilities of our PSM collection preferred grinding machineDue to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

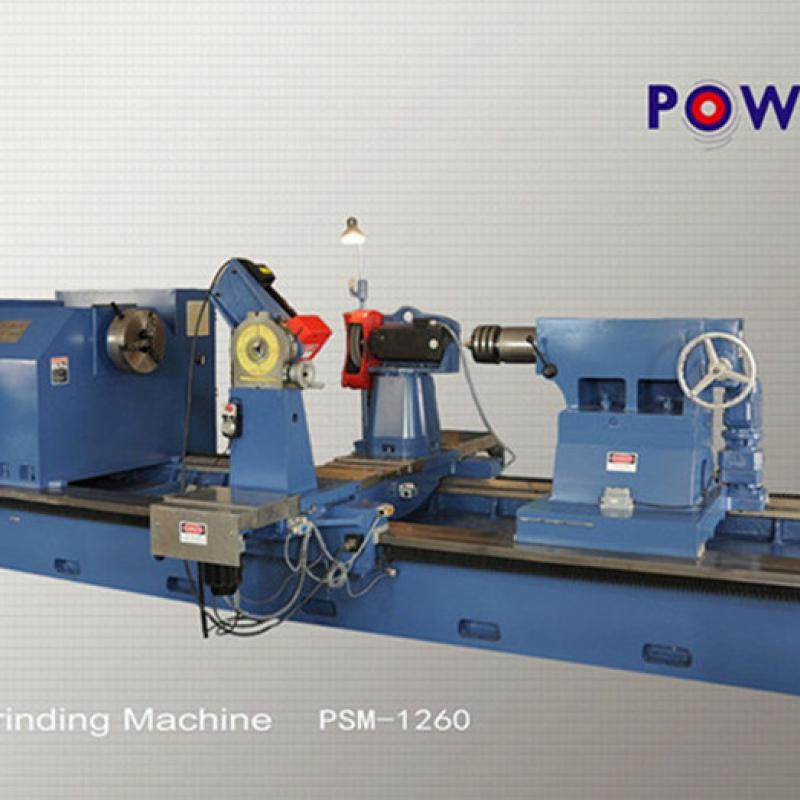

Factory Price Rubber Roller PolisherMore than 8 merchandise have been provided countrywide or shandong provincial stage product prizes and three scientific-studies achievement prizes. Packaging & ShippingPackaging detail of Factory Price Rubber Roller Polisher : 1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail: Within 2-4 weeks Our Services1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5. On-site training service provided.6.

Contact Now

1. Factory customized rubber roller groover has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

1. It has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.PSM-1680-CNC Rubber Roller Groover / Grooving / Grinder / Grinding MachinesDue to the all-round of the system function, it can make almost all the profile of rollers.

Contact Now

Factory Price Rubber Roller PolisherMore than eight products have been awarded National or Shandong Provincial level product prizes and three scientific-research achievement prizes. Packaging & ShippingPackaging detail of Factory Price Rubber Roller Polisher : 1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail: Within 2-4 weeks Equipment video:Our Services1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5.

Contact Now

PSM-1680-CNC Rubber Roller Groover / Grooving / Grinder / Grinding MachinesDue to the all-round of the system function, it can make almost all the profile of rollers.

Contact Now

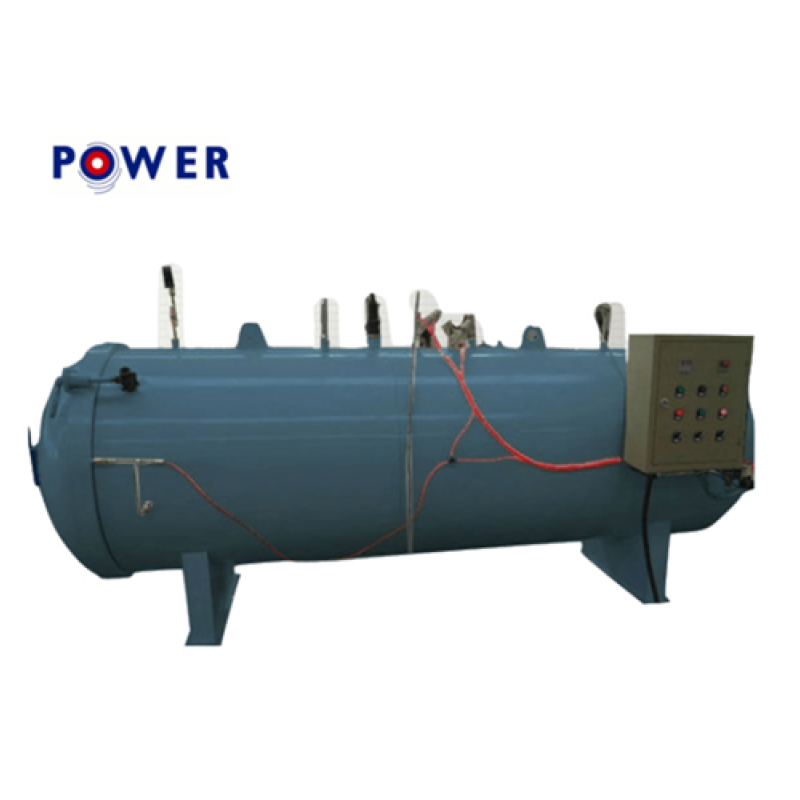

Product Description:Hydraulic system of vulcanizing tank: cover closing, cover locking and other actions in the operation of vulcanizing tank are completed by the hydraulic system. Hydraulic system includes relevant control valve, hydraulic control check valve, oil cylinder, etc., excluding oil pump. The design of hydraulic system meets the requirements of driving force and speed.Compressed air system of vulcanizing tank: the main function of compressed air system is to provide the power of pneumatic control valve and pneumatic cut-off valve.

Contact Now

Factory Price Rubber Roller PolisherMore than 8 merchandise have been provided countrywide or shandong provincial stage product prizes and three scientific-studies achievement prizes. Packaging & ShippingPackaging detail of Factory Price Rubber Roller Polisher : 1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail: Within 2-4 weeks Equipment video:Our Services1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5.

Contact Now

Feature:Composed of five main systems: hydraulic system, air pressure system, vacuum system, steam system and automatic control system.Triple interlock protection ensures the safety.100% X-ray inspection to ensure product quality.Fully automatic control, accurate temperature control and pressure, energy saving. Product Description:Hydraulic system of vulcanizing tank: cover closing, cover locking and other actions in the operation of vulcanizing tank are completed by the hydraulic system.

Contact Now

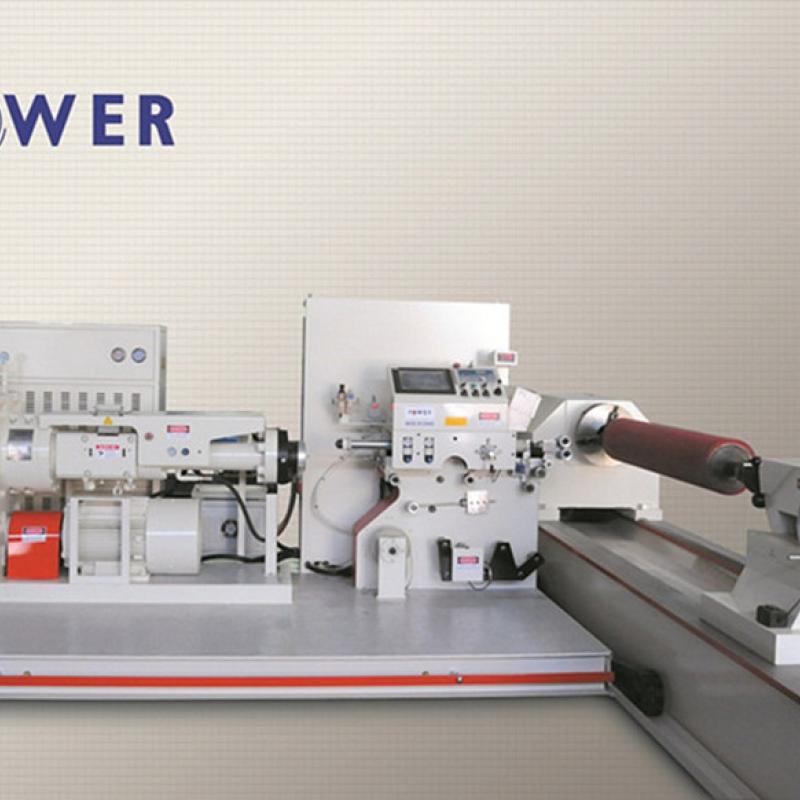

1.in particular designed through energy for precise pleasant manage of rubber rollers.2. along with the most superior laser probe. making dimension for any apparent tolerance and roughness on surface of rubber rollers.3. connecting to computer without problems for statistics's transmission and analysis.4. person friendly running gadget.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contact Now

1.in particular designed through energy for precise pleasant manage of rubber rollers.2. along with the most superior laser probe. making dimension for any apparent tolerance and roughness on surface of rubber rollers.3. connecting to computer without problems for statistics's transmission and analysis.4. person friendly running gadget.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contact Now

Roller Boiler Standerand Configurations: -Diameter 1500 * Length 4000 mm -Material: Q345R -Thickness of the vulcanizer: 8mm -Thickness of the end enclosure: 8mm -Designed pressure: 0.85mpa -Designed temperature: 180C -Automatic heating vulcanizer, temperature, pressure, and heating time, are controled by computer.

Contact Now

Factory Price Rubber Roller PolisherMore than eight products have been awarded National or Shandong Provincial level product prizes and three scientific-research achievement prizes. Packaging & ShippingPackaging detail of Factory Price Rubber Roller Polisher : 1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail: Within 2-4 weeks Our Services1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5. On-site training service provided.6.

Contact Now

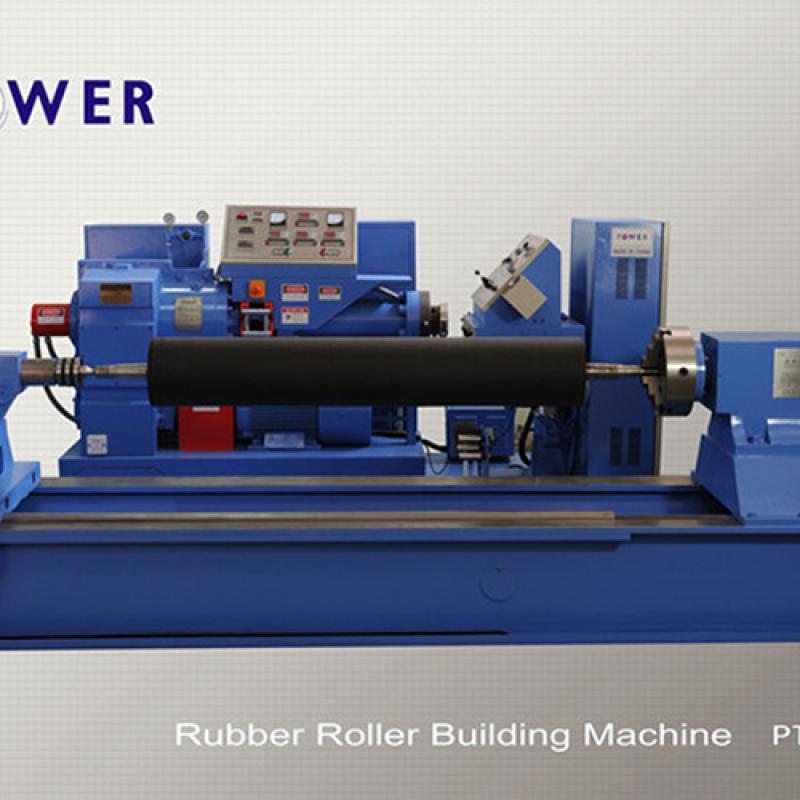

PTM-1510 Printing Rubber Roller ExtruderJinan Power Rubber Roller Equipment Company`s technology is intended to increase the productivity of rubber roller industry. PTM-1510 rubber roller extruderThese models are suitable for processing big type paper making and mine transmission rubber rollers and other industrial transmission rollers. Extruder is especially designed for the rubber roller manufacture. These two modes are equipped with E350CS power extruder and the industrial cooling system. It equip with high degree automatic control system.

Contact Now

1.Specially designed by POWER for precise quality control of rubber rollers.2. Consisting of the most advanced laser probe. Making measurement for any apparent tolerance and roughness on surface of rubber rollers.3. Connecting to PC easily for data's transmission and analysis.4. User friendly operating system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

Roller Boiler Standerand Configurations: -Diameter 1500 * Length 4000 mm -Material: Q345R -Thickness of the vulcanizer: 8mm -Thickness of the end enclosure: 8mm -Designed pressure: 0.85mpa -Designed temperature: 180C -Automatic heating vulcanizer, temperature, pressure, and heating time, are controled by computer.

Contact Now

Due to the all-spherical of the machine function, manufacturing unit custom designed rubber curler groover could make nearly all of the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, instantly groove, horizontal groove and different formations withinside the appended drawing.1.

Contact Now

PCM Multi-Purpose Stripping Machine is eparticularly researched, evolved and designed for treating vintage Rubber Rollers. PCM Multi-cause Stripping Machine has the benefits that: Old rubber may be quick eliminated through a unique ring cutter, a curler middle could have a brand-new floor beneathneath the unique belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the curler middle is ensured, which changed the conventional sand blasting process.

Contact Now

QUALITY CONTROL Precisely checked with our own made PSF series rubber roller laser measuring instrument. APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.PRODUCTIONBeing extremely strict with the production process.Various necessory working procedures to ensure the most reliable quality

Contact Now

Product Descriptin:Hydraulic system of vulcanizing tank: cover closing, cover locking and other actions in the operation of vulcanizing tank are completed by the hydraulic system. Hydraulic system includes relevant control valve, hydraulic control check valve, oil cylinder, etc., excluding oil pump. The design of hydraulic system meets the requirements of driving force and speed.Compressed air system of vulcanizing tank: the main function of compressed air system is to provide the power of pneumatic control valve and pneumatic cut-off valve.

Contact Now

PTM-1510 Industrial Rubber Roller ExtruderJinan Power Rubber Roller Equipment Company`s technology is intended to increase the productivity of rubber roller industry. PTM-1510 rubber roller extruderThese models are suitable for processing big type paper making and mine transmission rubber rollers and other industrial transmission rollers. Extruder is especially designed for the rubber roller manufacture. These two modes are equipped with E350CS power extruder and the industrial cooling system. It equip with high degree automatic control system.

Contact Now

1.Specially designed by POWER for precise quality control of rubber rollers.2. Consisting of the most advanced laser probe. Making measurement for any apparent tolerance and roughness on surface of rubber rollers.3. Connecting to PC easily for data's transmission and analysis.4. User friendly operating system.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contact Now

Product descriptionFeatures of PTM-4030 Rubber Roller Coating Machine1.Applicable to production of printing Rubber Rollers and general rubber roller.2.Equipped with E250CS cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with hardness The hardness range is 15-100A.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPTM Series Rubber Roller Coating MachineThe automatic rubber roller Covering Machine is d

Contact Now

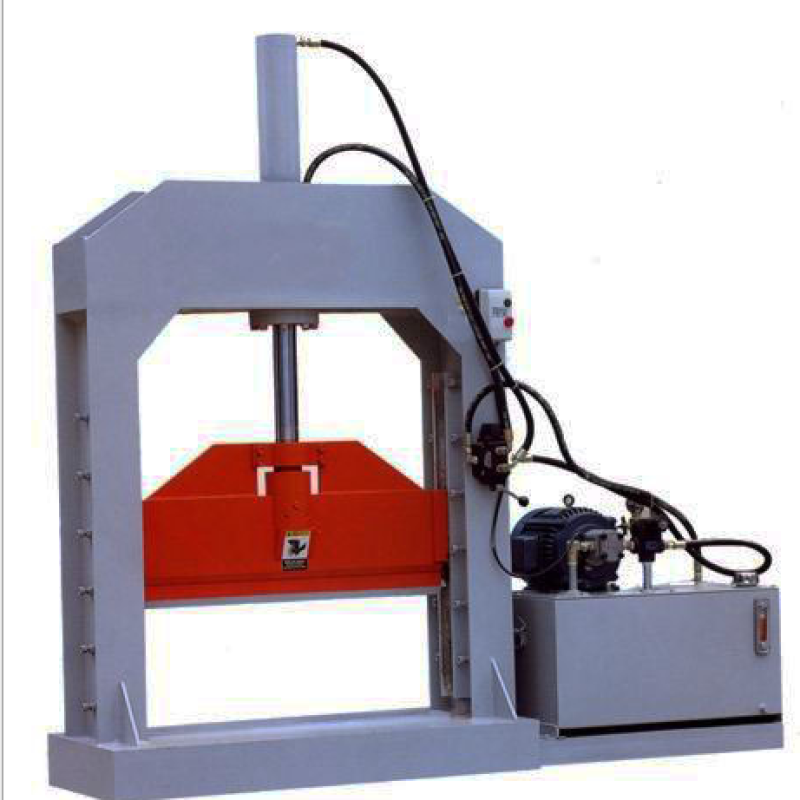

The Hydraulic rubber cutting machine The Hydraulic rubber cutting machine mainly has the cutting glue knife, the machine frame, the work oil cylinder, the base, the auxiliary work table and the hydraulic system, the electrical system and so on part composes, the cutting glue knife base is equipped with the nylon or the soft lead backing plate, protects the cutting knife the blade.Raw gum, with artificial glue in the cutting knife below, and then press the Start button, then the cutting knife in the piston rod driven by the slide along the rack down the rubber material cut.The ra

Contact Now