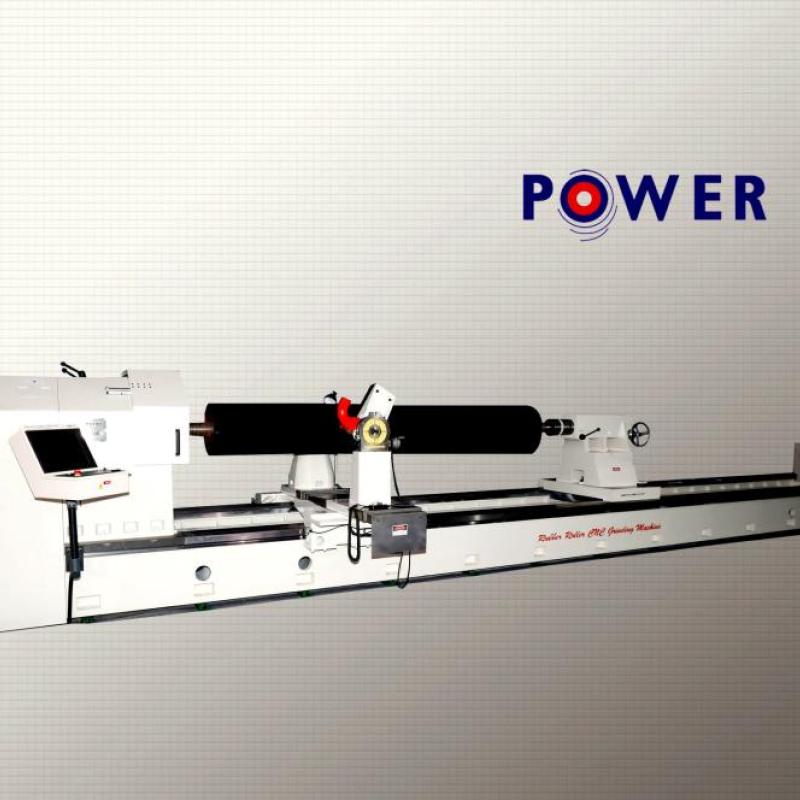

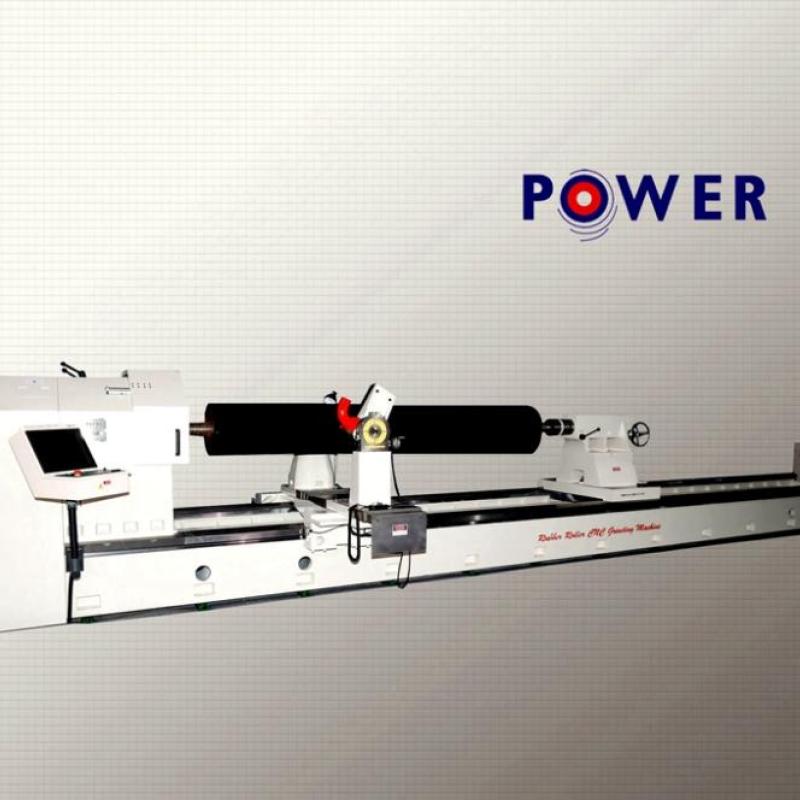

Because of the all-spherical of the device feature, manufacturing unit custom designed rubber roller groover could make nearly all of the profile of rollers. for instance, parabolic crowning and concave, cosine crowning and concave, round, cone, coarse pitch, herringbone, diamond, without delay groove, horizontal groove and exclusive formations within the appended drawing.1.

Contact Now

PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe. It can make measurement for any apparent tolerance and roughness on surface of rubber rollers.

Contact Now

Because of the all-round of the device function, manufacturing unit custom designed rubber roller groover could make almost all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, immediately groove, horizontal groove and different formations inside the appended drawing.1.

Contact Now

1.especially designed with the useful resource of strength for particular first-rate manage of rubber rollers.2. inclusive of the maximum advanced laser probe. making dimension for any obvious tolerance and roughness on floor of rubber rollers.3. connecting to pc effortlessly for facts's transmission and evaluation.4. consumer first-class working device.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contact Now

Due to the all-spherical of the machine function, manufacturing unit custom designed rubber curler groover could make nearly all of the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, instantly groove, horizontal groove and different formations withinside the appended drawing.1.

Contact Now

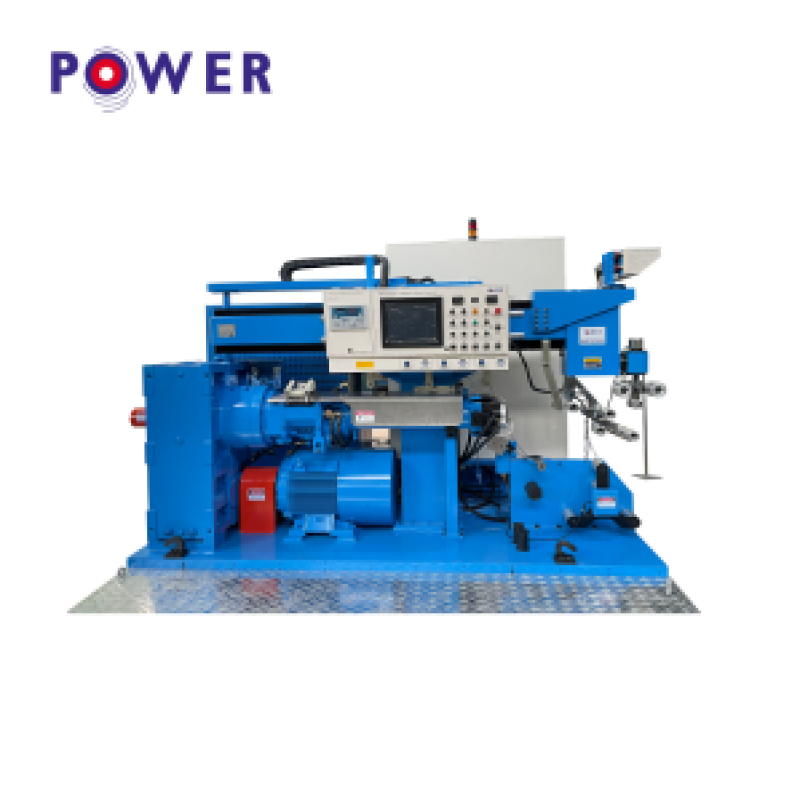

1. Factory customized rubber roller groover has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

Factory Price Rubber Roller PolisherMore than eight products have been awarded National or Shandong Provincial level product prizes and three scientific-research achievement prizes. Packaging & ShippingPackaging detail of Factory Price Rubber Roller Polisher : 1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail: Within 2-4 weeks Our Services1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5. On-site training service provided.6.

Contact Now

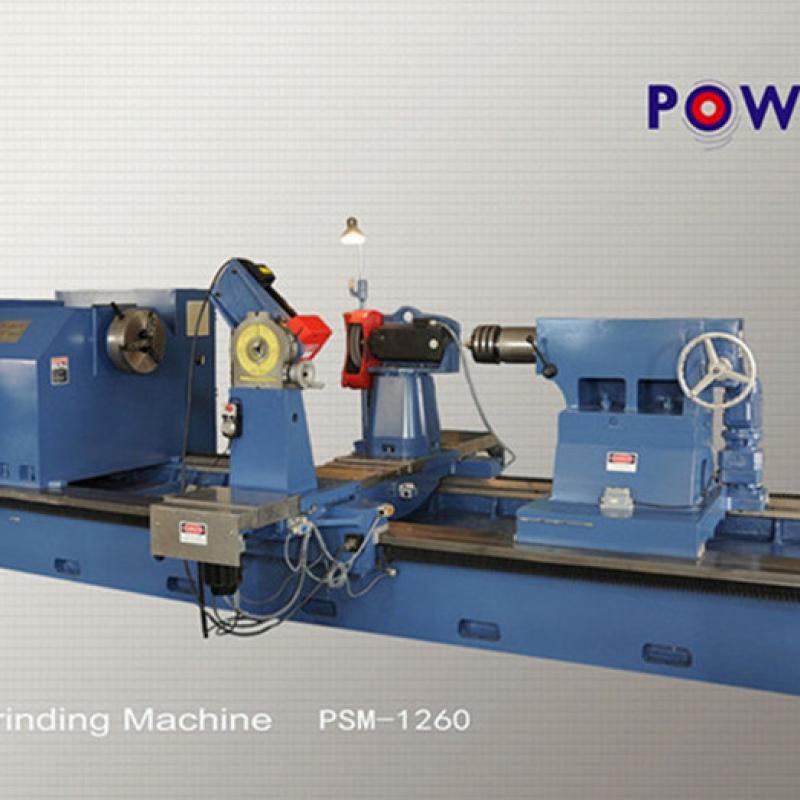

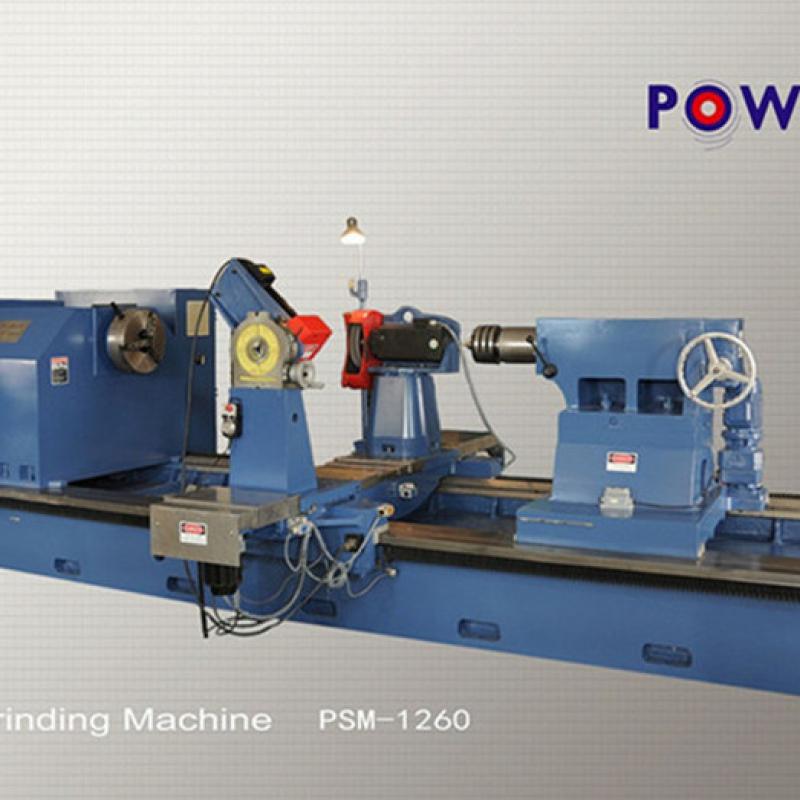

The feature of PSM series Jinan Rubber Roller CNC Roll Grinding MachineDue to the all-spherical of the machine function, manufacturing unit custom designed rubber curler groover could make nearly all of the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, instantly groove, horizontal groove and different formations withinside the appended drawing.1. Standard equipment of PSM series includes: a. a full flood recirculating coolant system b.

Contact Now

1. It has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.PSM-1680-CNC Rubber Roller Groover / Grooving / Grinder / Grinding MachinesDue to the all-round of the system function, it can make almost all the profile of rollers.

Contact Now

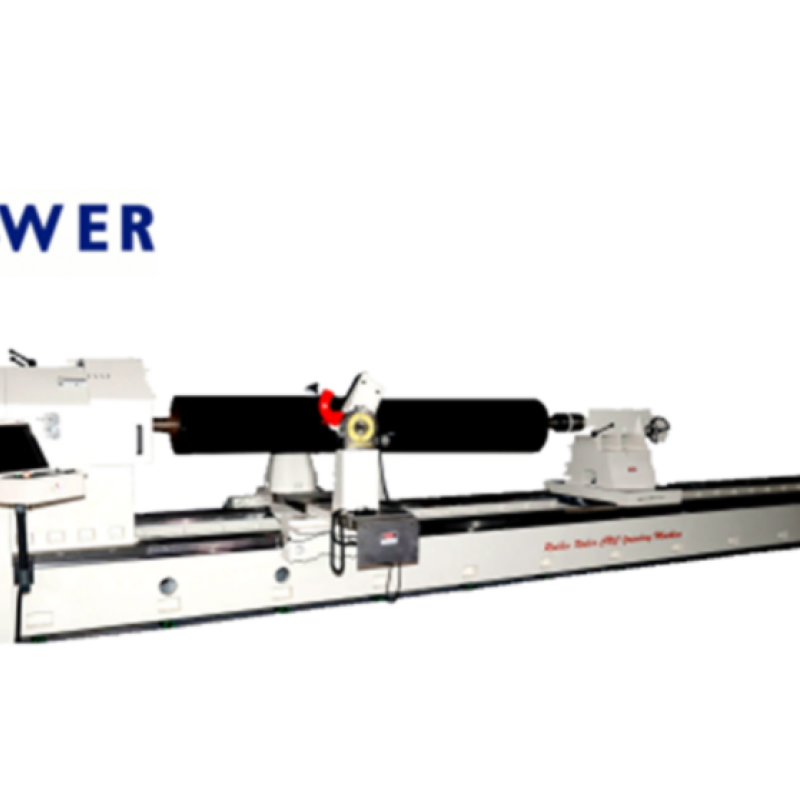

PSM-8040 General Rubber Roller Surface Grinding MachinePSM collection rubber curler grinding gadget is mainly designed and synthetic to replace the beyond roller processing approach by using way of steel production device. installation grinding head on the engine lathe is the past technique to fabricate curler, which the first-rate of curler is difficult to gain the requirement of the prevailing full-size. the primary purpose lies within the form of lathe.

Contact Now

APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.MATERIALAdopts specially formulated rubber compounds imported from the U.S.

Contact Now

APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.MATERIALAdopts specially formulated rubber compounds imported from the U.S.

Contact Now

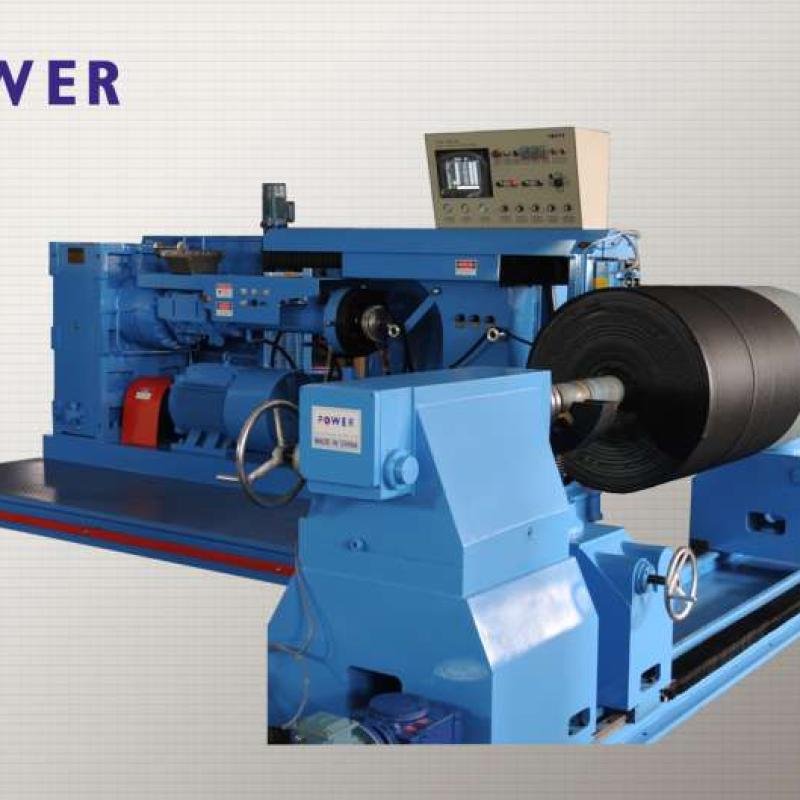

The feature of PSM series grinding machine for rubber roller processing1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd. front and rear independently operated carriage tablese. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3. Two medium carriage tables assembled to ensure accurate performance and operating stability.4. The max. linear speed of grinding head is over 90m/s.

Contact Now

PSM-8040 General Rubber Roller Surface Grinding MachinePSM series rubber roller grinding system is in particular designed and artificial to update the past curler processing technique with the aid of using the usage of manner of metallic manufacturing device. set up grinding head at the engine lathe is the beyond approach to manufacture roller, which the brilliant of roller is tough to benefit the requirement of the triumphing full-size. the number one reason lies withinside the shape of lathe.

Contact Now

PSM collection rubber curler grinding system is eparticularly designed and synthetic to update the beyond curler processing technique via way of means of metal production equipment. Mounted grinding head at the engine lathe is the beyond technique to fabricate curler, which the best of curler is tough to attain the requirement of the prevailing standard. The fundamental cause lies withinside the shape of lathe. After all, it isn't always the grinding system; the transferring areas of the large and medium carriage desk are large than that of grinding system.

Contact Now

Rubber Roller Surface Grinding Machine for Paper The feature of PSM series rubber roller surface grinding machine for paper 1 Standard equipment of PSM series includes a a full flood recirculating coolant system b motorized tailstock c variable speed traverse and spindle drives d front and rear independently operated.The feature of PSM series rubber roller surface grinding machine for paper1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contact Now

The feature of PSM series grinding machine for rubber roller processingPSM collection grinding system for rubber curler processing is eparticularly designed and synthetic to update the beyond curler processing approach via way of means of metal production equipment. Mounted grinding head at the engine lathe is the beyond approach to fabricate curler, which the pleasant of curler is hard to attain the requirement of the prevailing standard. The principal cause lies withinside the shape of lathe.

Contact Now

Factory Rubber Roller Grinding Machine For Textile The feature of PSM series factory rubber roller grinding machine for textile 1 Standard equipment of PSM series includes a a full flood recirculating coolant system b motorized tailstock c variable speed traverse and spindle drives d front and rear independently.The feature of PSM series factory rubber roller grinding machine for textile1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contact Now

Rubber Roller Surface Grinding Machine for Paper The feature of PSM series rubber roller surface grinding machine for paper 1 Standard equipment of PSM series includes a a full flood recirculating coolant system b motorized tailstock c variable speed traverse and spindle drives d front and rear independently operated.The feature of PSM series rubber roller surface grinding machine for paper1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contact Now

Factory Rubber Roller Grinding Machine For Textile The characteristic of PSM collection manufacturing facility rubber curler grinding device for fabric 1 Standard system of PSM collection consists of a a complete flood recirculating coolant machine b motorized tailstock c variable pace traverse and spindle drives d the front and rear independently.The feature of PSM series factory rubber roller grinding machine for textile1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contact Now

Grinding Machine for Rubber Roller MakingThe feature of PSM series Grinding Machine for Rubber Roller MakingPSM series Factory Automatic Cylindrical Roll Grinder is specially designed and manufactured to replace the past roller processing method by metallic manufacturing equipment. Mounted grinding head on the engine lathe is the past method to manufacture roller, which the quality of roller is difficult to reach the requirement of the present standard. The main reason lies in the structure of lathe.

Contact Now

1. Factory customized rubber roller groover has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

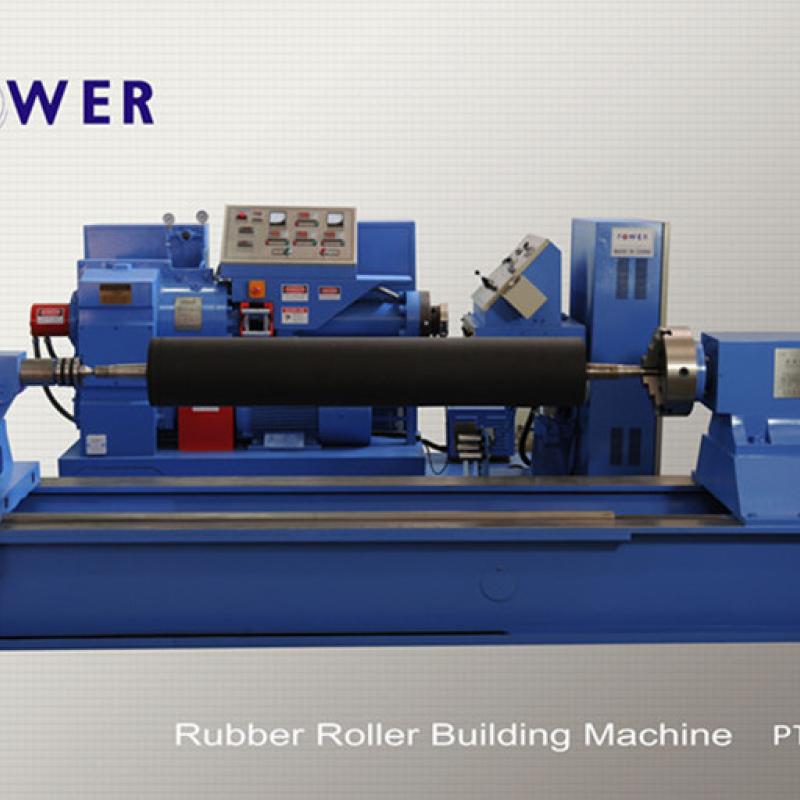

Product descriptionThe NBR Rubber Roller Covering Machine Hot Sale is designed and produced for improving the rubber covering process.

Contact Now

Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, straight groove, horizontal groove and other formations in the appended drawing.1.

Contact Now