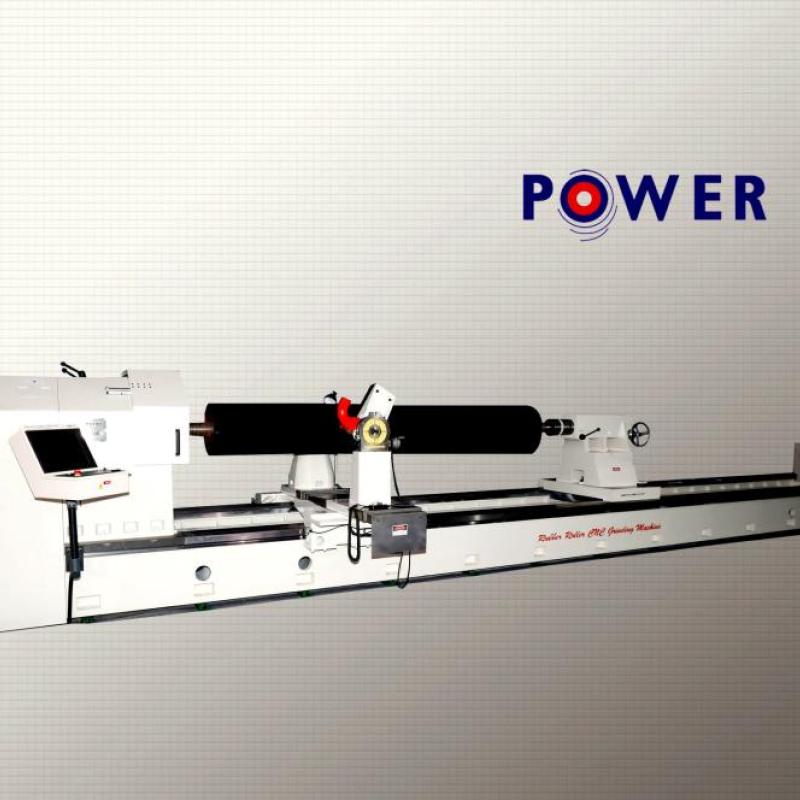

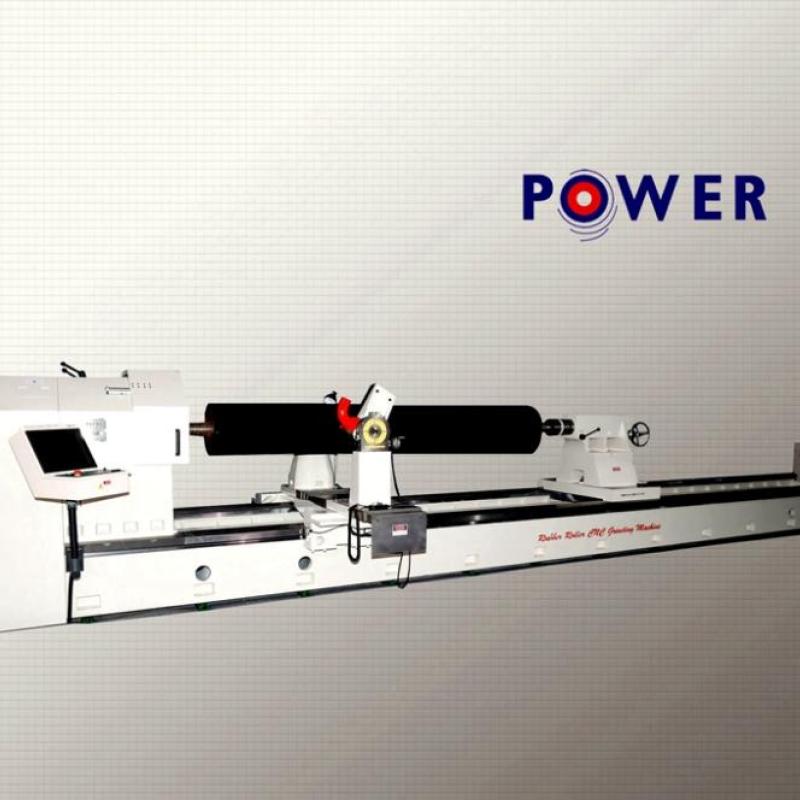

Because of the all-round of the device function, manufacturing unit custom designed rubber roller groover could make almost all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, immediately groove, horizontal groove and different formations inside the appended drawing.1.

Contact Now

APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.MATERIALAdopts specially formulated rubber compounds imported from the U.S.

Contact Now

APPLICATION FIELDSAs an experienced custom rubber roller manufacturer in China, we supply various rollers for different field.- Roller for wide digital printing machine.- Roller for paper milled machinery.- Roller for textile machinery.- Roller for plastic film machinery.- Roller for plywood conveyor system.- Roller for mine and filter industry.MATERIALAdopts specially formulated rubber compounds imported from the U.S.

Contact Now

Because of the all-round of the device characteristic, manufacturing unit customized rubber curler groover should make nearly all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, right now groove, horizontal groove and different formations inside the appended drawing.1.

Contact Now

Psf rubber curler surface measuring instrument is specifically designed and manufactured for rubber roller production firms. it's a kind of unique testing device include the most advanced laser probe. it can make dimension for any apparent tolerance and roughness on floor of rubber rollers.

Contact Now

1.especially designed with the useful resource of strength for particular first-rate manage of rubber rollers.2. inclusive of the maximum advanced laser probe. making dimension for any obvious tolerance and roughness on floor of rubber rollers.3. connecting to pc effortlessly for facts's transmission and evaluation.4. consumer first-class working device.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contact Now

Psf rubber roller surface measuring instrument is in particular designed and synthetic for rubber roller manufacturing firms. it's a kind of specific checking out tool encompass the maximum superior laser probe. it is able to make dimension for any apparent tolerance and roughness on ground of rubber rollers.

Contact Now

Packaging & ShippingPackaging detail: 1. Outside package: Standard export wooden cases.2. Inner package: Stretch film.Shipping detail: Within 2-4 weeksWith the mindset of being expert and sincere, strength agency produces super rubber rollers intently following sci-tech requirement of the instances.

Contact Now

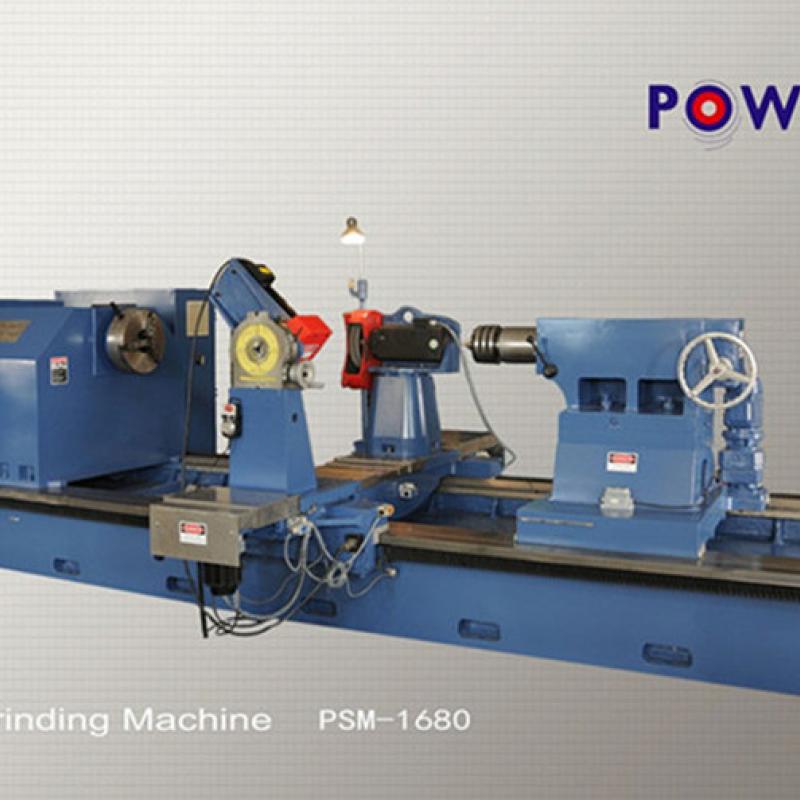

PSM series grinding machine for rubber roller processing is specially designed and manufactured to replace the past roller processing method by metallic manufacturing equipment. Mounted grinding head on the engine lathe is the past method to manufacture roller, which the quality of roller is difficult to reach the requirement of the present standard. The main reason lies in the structure of lathe. After all, it is not the grinding machine; the moving spaces of the big and medium carriage table are larger than that of grinding machine.

Contact Now

PSM-4020 General Rubber Roller Surface Grinding MachinePSM series rubber roller grinding gadget is specifically designed and synthetic to replace the beyond curler processing method by way of metallic production equipment. set up grinding head at the engine lathe is the beyond approach to fabricate roller, which the high-quality of roller is hard to attain the requirement of the present widespread. the primary cause lies inside the shape of lathe. in the end, it isn't the grinding gadget; the shifting spaces of the large and medium carriage desk are large than that of grinding device.

Contact Now

PSM collection rubber curler grinding system is eparticularly designed and synthetic to update the beyond curler processing technique via way of means of metal production equipment. Mounted grinding head at the engine lathe is the beyond technique to fabricate curler, which the best of curler is tough to attain the requirement of the prevailing standard. The fundamental cause lies withinside the shape of lathe. After all, it isn't always the grinding system; the transferring areas of the large and medium carriage desk are large than that of grinding system.

Contact Now

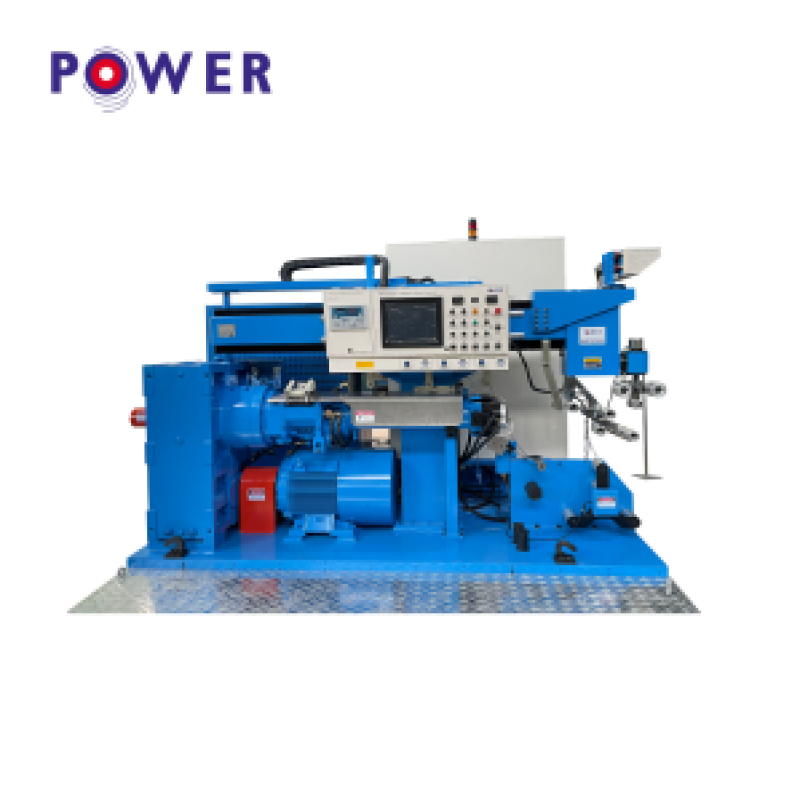

Product descriptionFeatures of PTM-4030 Rubber Roller Coating Machine1.Applicable to production of printing Rubber Rollers and general rubber roller.2.Equipped with E250CS cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with hardness The hardness range is 15-100A.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPTM Series Rubber Roller Coating MachineThe automatic rubber roller Covering Machine is d

Contact Now

Product description1. This equipment is designed as a follow up machine of our PSM series for the rubber roller surface refining process.2. Meeting critical requirements on the surface smoothness by choosing the abrasive band with different granularity.3. The geometric size of rubber roller will remain unchanged.4. The operating system is simple and easy-to-use.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

PSM-8040 General Rubber Roller Surface Grinding MachinePSM collection rubber curler grinding gadget is mainly designed and synthetic to replace the beyond roller processing approach by using way of steel production device. installation grinding head on the engine lathe is the past technique to fabricate curler, which the first-rate of curler is difficult to gain the requirement of the prevailing full-size. the primary purpose lies within the form of lathe.

Contact Now

Product descriptionFeatures of PTM-4030 Rubber Roller Coating Machine1.Applicable to production of printing Rubber Rollers and general rubber roller.2.Equipped with E250CS cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with hardness The hardness range is 15-100A.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPTM Series Rubber Roller Coating MachineThe automatic rubber roller Covering Machine is d

Contact Now

Rubber Roller Surface Grinding Machine for Paper The feature of PSM series rubber roller surface grinding machine for paper 1 Standard equipment of PSM series includes a a full flood recirculating coolant system b motorized tailstock c variable speed traverse and spindle drives d front and rear independently operated.The feature of PSM series rubber roller surface grinding machine for paper1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contact Now

Factory Rubber Roller Grinding Machine For Textile The characteristic of PSM collection manufacturing facility rubber curler grinding device for fabric 1 Standard system of PSM collection consists of a a complete flood recirculating coolant machine b motorized tailstock c variable pace traverse and spindle drives d the front and rear independently.The feature of PSM series factory rubber roller grinding machine for textile1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contact Now

The feature of PSM series grinding machine for rubber roller processing1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd. front and rear independently operated carriage tablese. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3. Two medium carriage tables assembled to ensure accurate performance and operating stability.4. The max. linear speed of grinding head is over 90m/s.

Contact Now

The feature of PSM series grinding machine for rubber roller processingPSM collection grinding system for rubber curler processing is eparticularly designed and synthetic to update the beyond curler processing approach via way of means of metal production equipment. Mounted grinding head at the engine lathe is the beyond approach to fabricate curler, which the pleasant of curler is hard to attain the requirement of the prevailing standard. The principal cause lies withinside the shape of lathe.

Contact Now

Feature:Composed of five main systems: hydraulic system, air pressure system, vacuum system, steam system and automatic control system.Triple interlock protection ensures the safety.100% X-ray inspection to ensure product quality.Fully automatic control, accurate temperature control and pressure, energy saving. Product Description:Hydraulic system of vulcanizing tank: cover closing, cover locking and other actions in the operation of vulcanizing tank are completed by the hydraulic system.

Contact Now

1.in particular designed through energy for precise pleasant manage of rubber rollers.2. along with the most superior laser probe. making dimension for any apparent tolerance and roughness on surface of rubber rollers.3. connecting to computer without problems for statistics's transmission and analysis.4. person friendly running gadget.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contact Now

Factory Price Rubber Roller PolisherMore than eight products have been awarded National or Shandong Provincial level product prizes and three scientific-research achievement prizes. Packaging & ShippingPackaging detail of Factory Price Rubber Roller Polisher : 1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail: Within 2-4 weeks Equipment video:Our Services1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5.

Contact Now

Due to the all-spherical of the machine function, manufacturing unit custom designed rubber curler groover could make nearly all of the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, instantly groove, horizontal groove and different formations withinside the appended drawing.1.

Contact Now

Product Description:1. Enhance the intensity of the Open Mill machine body by using more carbon steel and less wrought iron.2. The rubber open mixer machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now